Technical parameters

| Cutting kerf | 1,8-4,2 mm |

| Bandsaw blade width | 50-320 mm |

| Processing | Primary |

| Tooth finishing | Stellited |

| Service and sharpening | Yes |

| Material | Uddeholm, 80NiCr11, EHS |

Ripper bandsaw blades can be also purchased online

Normal delivery time

7 working days

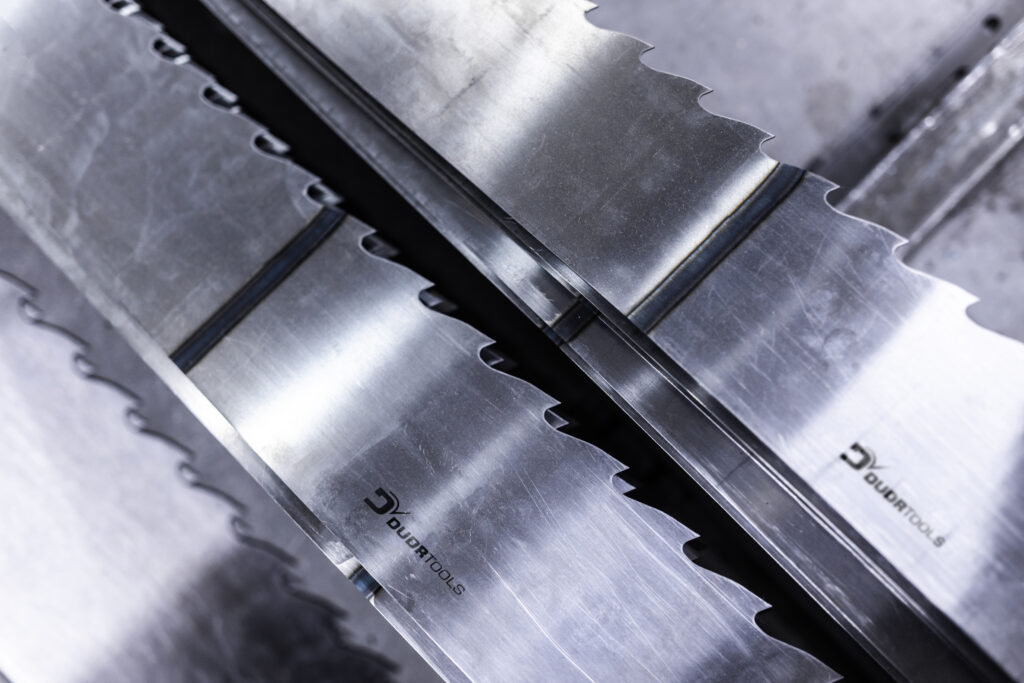

Wide bandsaw blades are the core sector of our production

Features

Wide bandsaw blades are intended for the primary processing of wood on bandsaw machines, they are commonly used by sawmills in the Czech Republic and abroad. Our production mainly consists of bandsaw blades made from the material Uddeholm, it is a top-quality Swedish steel that is highly resistant to wear and tear, manufactured by a worldwide recognised producer Voestalpine. We also offer the production of bandsaw blades from more economical materials (80NiCr11, EHS, etc.), which are still very valued materials.

Usage

The latest manufacturing processes enable us to produce bandsaw blades up to 320 mm wide. We manufacture them to order for various types of bandsaw blade machines, e.g. Lignotech, Hejtmánek, Lisý, Serra, Wimmer, Mebor, Wravor, Resch, Primultini, Bongioanni, EWD, etc. We always adapt the specific parameters of the wide bandsaw blade to the characteristics of the bandsaw machine and the customer’s needs.

Design

We supply welded and toothed bandsaw blades in these modifications:

- Stellite – tipped – is a modern treatment of the tooth ´ s cutting edge, where a special cobalt – and a chrome-based alloy containing some other components is welded on the tooth tips, constituting the cutting blade of a tooth after grinding. The tips are consequently very hard and wear-resistant, having a longer service life and longer sharpening interval. The stellite-tipped blades also enable a higher feeding speed and guarantee time-saving thanks to the less frequent need for tool replacement.

Welding

The main welds on bandsaw blades. These are up to 210 mm wide are butt-welded on Ideal welding machines. It is the best thermoplastic unit welding technology. The weld has a homogeneous structure, which makes it very hard and resistant. Our main welds are guaranteed for life.

Service

We provide full-scale servicing of wide bandsaw blades. For example, levelling and tensioning, which compensates for the unevenness of the belt body and gives it sufficient tension to ensure its stability in the cut which straightens any irregularities of the bandsaw blade and provides the bandsaw blade with sufficient tension, ensuring the blade ´ s cutting stability. We also provide a repair service for bandsaw bodies, sharpening and we can renew the stellite.

Have a question?

Contact us.

Do you have any question? Fill in a short questionnaire and we´ll get back to you within the next business day.